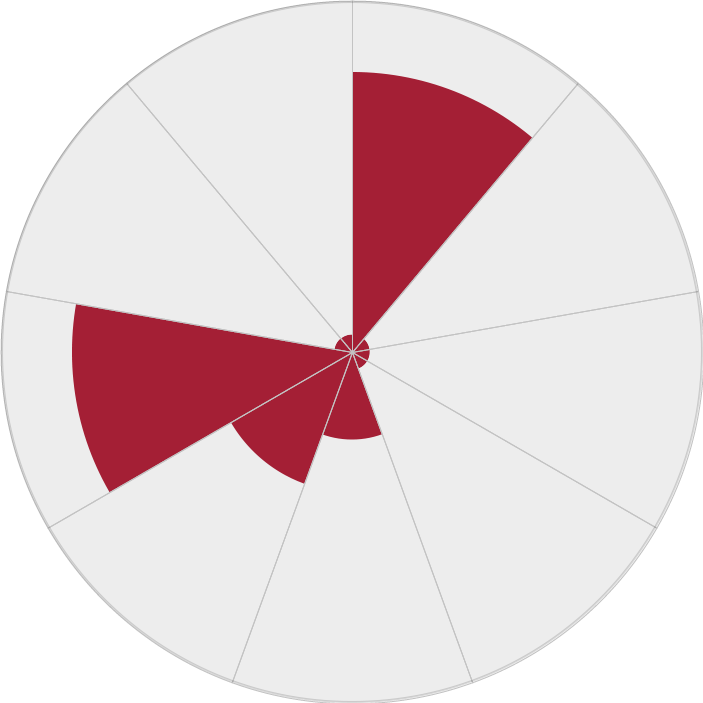

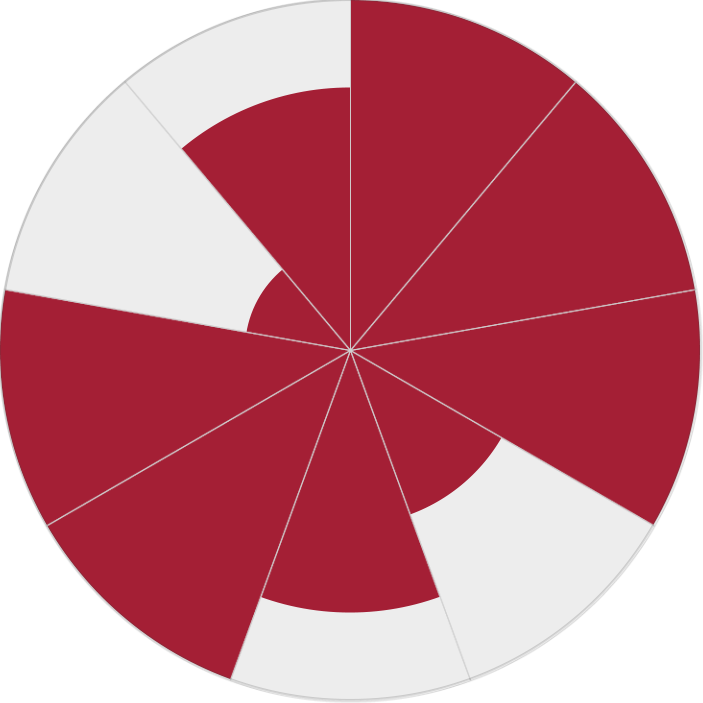

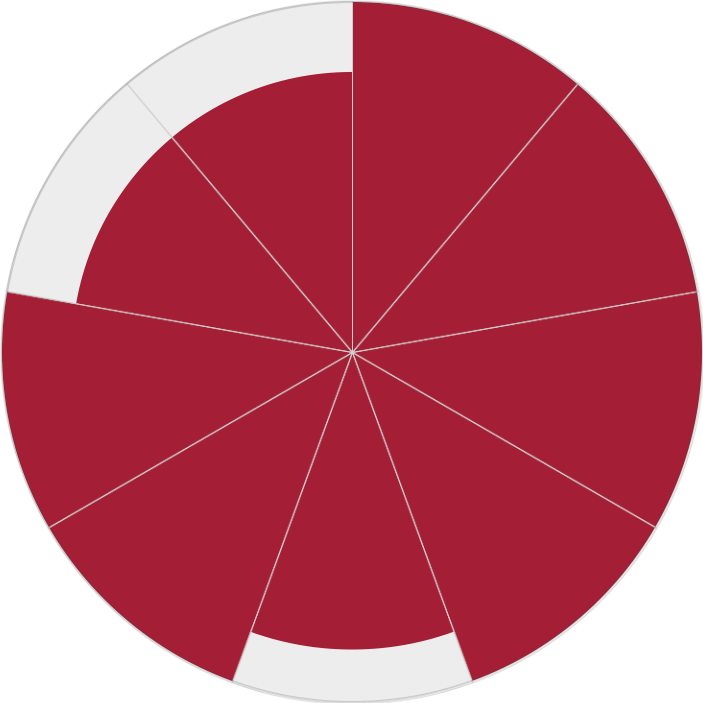

A versatile board, intended for the most demanding processes

Analyzing up to 9 of the most common processes in use, particleboard covers only the most basic requirements. SuperPan not only performs better in these processes, but allows its use in more demanding ones with performances closer to MDF.

Aglomerado

Superpan

MDF

WHAT DOES THIS GRAPH MEAN?

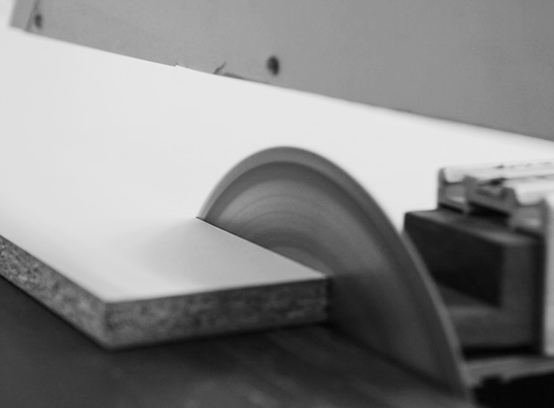

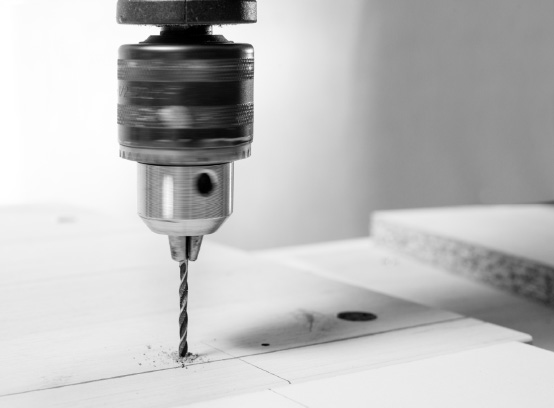

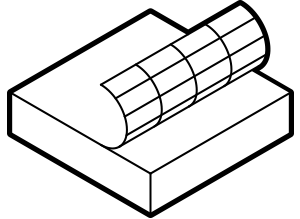

Machined

superPan responds efficiently and with advantages in most of the different machining processes to which a board can be subjected during the usual industrial transformation.

Coating

The excellent properties of the superPan wood fiber surface position it as an ideal solution for the different decorative coatings